Areas of Vigilance

Bells and equipment are put to the test

Used thousands of times over the course of a year, bell equipment requires effective maintenance and monitoring to safeguard the installation.

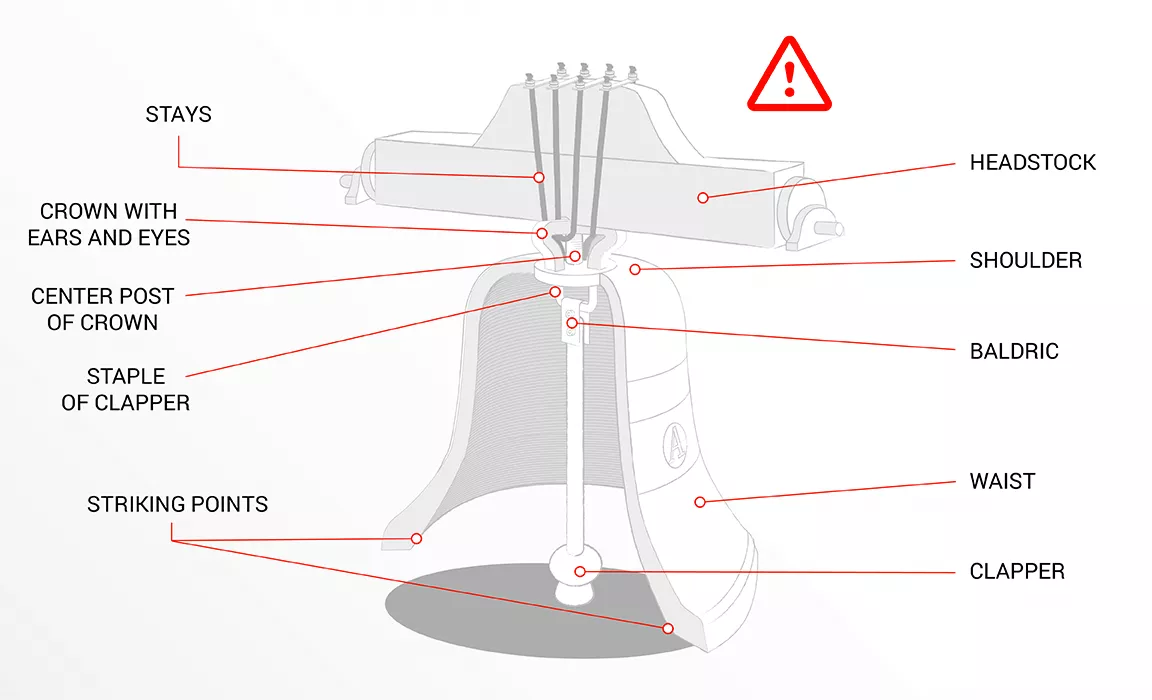

Areas of vigilance on a bell

The striking points

Accumulated years of ringing wears the striking points inside the bell and may lead to cracks in its structure.

Refilling striking points consists of welding new metal to parts of the bell that have been worn down by the clapper, to restore the bell to its original thickness. This operation does not change the tone of the bell, on the contrary, it increases the duration of the vibration.

The core and the crown

The head is the central part of the top of the bell located between the crown staple and the canons. Rust on the crown staple can cause the head of the bell to crack.

The crown is the top part of the bell on which the canons are installed. Any casting defects and/or cracking of the head cause cracks in the crown.

The stays and the canons

The stays are flat or round metal parts used to hang the bell on the headstock. Stays are machined or forged in the traditional manner Improperly tightened stays wear the canons on a bell.

Ringing

Ringing consists of swinging the bell smoothly from the headstock. Ringing devices that cause the bell to swing too much can weaken it on the striking points.

Today, the electronically controlled ringing motor can be used to program the start, swing and braking of the bell. It is designed to limit wear on the bell striking points and the efforts on the belfry.

The clapper

The clapper is a part made of mild steel, machined or cast, suspended inside the bell from the crown staple. The clapper hits the inside edge of the bell when it is swung to ring the bell. A clapper that is worn, incorrectly sized or made of material that is too hard will cause cracks.

The headstock

The headstock (also called “yoke”) is a piece of oak or metal on which the bell is hung and used to ring the bell by swinging. The whole assembly including the headstock with stays, balancing weights and arms is called the “bellframe”. Shrinking of the headstock due to natural drying of the wood requires the stays to be retightened.

The crown staple

The crown staple is a steel ring welded inside the crown of the bell and used to hang the clapper. Depending on the ringing method (handstroke, backstroke, etc.), the crown staple may come in different shapes. Rusting of the crown staple can cause cracks in the crown.

The baldric

The baldric is a traditionally leather strap of several thicknesses, used to suspend the clapper from the crown staple inside the bell. The baldric is looped onto the clapper.

For security, a metal tie keeps the striking length constant and strengthens the baldric. Over time and in the event of a defect, its wear can cause the clapper to fall.

In some cases (see photo), a clamp is added to the baldric to enable the bell to be turned through 90°. This manipulation should not be carried out as it can damage the bell on all four sides.

Inspection points on the bell and the headstock